CBIMK - Hollow Cone Spray Nozzle

Features

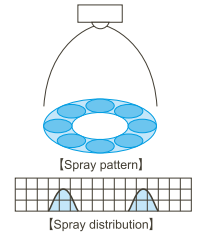

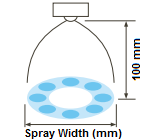

Hollow cone spray pneumatic nozzle producing fine atomization with a mean droplet diameter of 100 μm or less (*1).

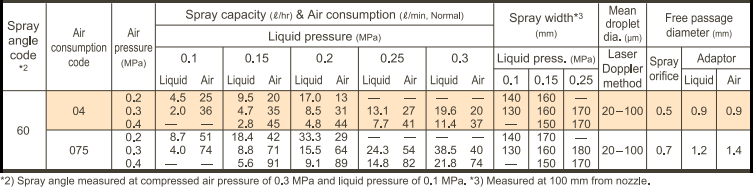

Features large turn-down ratio under liquid pressures of 0.1 – 0.3 MPa (ca. 1 bar – 3 bar).

Spray angle of 60º.

*1) Measured by Laser Doppler Method.

| Thread standard | - |

| Pipe conn. size | M3 depth 2 |

| Standard pressure | - |

| Spray angle | 60° |

| Spray capacity | 2.0 - 38.5 ℓ/hr |

| Supply air type | Compressed air |

| Liquid feeding system | Liquid pressure |

| Mean droplet diameter | 20 - 100 μm |

| Air consumption | 13–91 ℓ/min, Normal |

| Air pressure | 0.2 - 0.4 MPa (ca. 2 bar - 4 bar) |

| Free passage diameter | 0.5 - 0.7 mm |

Applications

Spraying: Mold release agent, lubricant, deodorant (trash pit, refuse collector, inlet conduit), oil,

surface treatment agent, rust preventive, honey, insecticide, aqueous urea, etc.

Cooling: Dies, gas, glass, steel plates, steel pieces, moldings, automobile bodies, plastic products, etc.

Moisture control: Paper, gas, ceramics, concrete, etc.

Structure and Materials

• Comprising 4 parts : Spray tip, core, cap and adaptor.

• Internal mixing type designed to mix compressed air and liquid inside the nozzle

(Inner air type : compressed air flows in the center of the nozzle, while liquid flows along its circumference).

• Liquid pressure type.

| NO. | Components | Standard Material |

| 1 | Spray Tip | S303 |

| 2 | Core | S303 |

| 3 | Cap | S303 |

| 4 | Connector | S303 |

| Air consumption code | Dimension | Pipe connection size | Mass (g) | ||||||

| L1 | L2 | L3 | L4 | H | Compressed air | Liquid | Fixing | ||

| 005 | 27.7 | 19.2 | 8 | 2.5 | 13 | M5 Depth 3 | M5 Depth 3 | M3x2 | 22 |

| 01 | 27.7 | 29.2 | |||||||

| 02 | 28.0 | 29.5 | |||||||

| 04 | 31.3 | 22.8 | |||||||

| 075 | 32.6 | 24.1 | |||||||